Magnetic door stops are great for protecting walls and keeping doors secure, but DIY installations often fail due to common mistakes. To get it right, avoid these seven errors:

- Poor Alignment: Misaligned magnets weaken holding power. Use a level and keep the gap under 3mm.

- Wrong Screws: Match screws to door material (wood, metal, hollow-core) and ensure at least 1-inch penetration.

- Ignoring Door Movement: Consider door weight, hinge condition, and swing patterns.

- Incorrect Magnet Strength: Match magnet power to door weight (1 lb force per 10 lbs of door weight).

- Skipping Surface Prep: Clean surfaces with isopropyl alcohol and ensure they’re dry before installation.

- Height Errors: Install at ¾ of the door’s height for optimal performance.

- No Function Tests: Test hold strength, movement, and environmental conditions before finalizing.

Everbilt Magnetic Doorstop Installation

1. Poor Magnet Alignment

Getting the alignment right is essential - just a small misalignment (as little as 1/8" or 3mm) can weaken the holding power significantly[4]. Here’s what to focus on:

Vertical Positioning

Always use a level tool for accuracy. Eyeballing it might seem quick, but it often leads to mistakes[6].

Horizontal Alignment

Make sure the strike plate is positioned to follow the door's swing arc, not just placed perpendicular to the magnet[5].

Depth Alignment

The gap between the magnet and the strike plate is critical. A larger gap means less magnetic force. Keep the distance as small as possible - ideally no more than 3mm[2].

| Issue | Result | Fix |

|---|---|---|

| Vertical Misalignment | Reduced holding power | Use a laser level to ensure precise marking |

| Horizontal Offset | Inconsistent door catching | Adjust placement to match the door's swing arc |

| Incorrect Depth | Weak magnetic connection | Keep the gap under 3mm for optimal strength |

Mark positions with a pencil before installation to avoid mistakes. For the best results, recheck the alignment a few weeks after setting everything up.

Alignment issues are common but easy to avoid if you use the right tools. Speaking of tools, the next problem often comes down to hardware selection.

2. Wrong Screw Types

Using the right screws for your door material is essential to ensure a secure and lasting installation.

Material Matters

| Door Type | Recommended Screw Type | Tip |

|---|---|---|

| Wood | Coarse-threaded wood screws | Pre-drill to avoid splitting |

| Metal | Self-tapping sheet metal screws | Use the correct pilot hole size |

| Composite | Fine-threaded specialty screws | Avoid over-tightening |

| Hollow-core | Hollow wall anchors/toggle bolts | Requires a special mounting method |

Length and Size Guidelines

Screws need to penetrate at least 1 inch (25mm) into solid framing [5]. To determine the correct length, add the thickness of the door stop to the minimum frame penetration depth (1 inch for wood).

Corrosion Considerations

Choose screws based on the environment where the door is installed:

- Stainless steel screws are ideal for exterior doors or areas with high moisture.

- Zinc-plated steel screws work well for interior doors in dry spaces [8].

- Match the screw material to the door stop's finish to avoid metal reactions [8].

Common Failure Points

Failures often happen due to:

- Using screws that are too short, which reduces grip strength.

- Mismatched materials, leading to stripping or loosening.

- Corrosion in humid or damp environments.

Even with the right hardware, problems can arise if the door’s movement patterns aren’t considered. This brings us to the next critical issue.

3. Door Movement Issues

Placing a magnetic door stop without considering how the door moves in everyday use can lead to problems. Even with perfect alignment (as discussed in Section 1), ignoring movement patterns can weaken the magnetic hold. Before installation, it’s essential to evaluate these factors:

Movement Pattern Analysis

| Factor | Impact |

|---|---|

| Door Weight | Heavier doors (50+ lbs) require stronger magnets with 20-25 lb pull force [9]. |

| Floor Surface | The material affects how the door swings. |

| Hinge Condition | Loose or worn hinges lead to unpredictable movement. |

Common Movement-Related Failures

Movement issues often result in problems like sagging doors or inconsistent swings caused by loose hinges [5]. These can reduce the effectiveness of a magnetic stop, making it less reliable over time.

Proper Placement Strategy

For the best results, position the magnetic door stop about ¾ of the door’s height from the floor [2]. This placement offers several benefits:

- Stronger hold due to better alignment with the magnet’s pull force.

- Less stress on components, extending their lifespan.

- Improved durability, even with frequent use.

Environmental Considerations

StealthStop’s stainless steel design is built to endure tough conditions, such as coastal humidity and fluctuating temperatures.

Testing Before Permanent Installation

Before committing to a final placement, test the positioning with these quick checks:

- Map out the door’s natural swing arc.

- Simulate wind pressure to see how the door reacts.

- Inspect for any warping that could affect alignment [4].

Using temporary adhesive during the testing phase makes adjustments easy and ensures the magnet’s strength aligns with how the door operates in real life [2]. These steps help you avoid installation errors and prepare for the next critical factor.

4. Incorrect Magnet Strength

Finding the right balance between holding power and ease of use is key when installing magnetic door stops. Misjudging this can lead to performance issues.

Calculating the Right Force

A good rule of thumb: use 1 lb of magnetic force for every 10 lbs of door weight. For instance, a 50-lb door would need about 5 lbs of magnetic force [1]. Keep in mind the door's size and how often it's used when making these calculations.

How Door Material Affects Performance

The material of the door plays a big role in how well the magnet works [7]:

- Steel doors: Provide the best magnetic connection.

- Wooden doors: Usually need an extra metal plate for proper function.

- Aluminum or glass doors: Require special mounting adapters to work effectively.

Factors in the Environment

Environmental conditions like temperature and humidity can impact magnet performance [10]:

- High temperatures can weaken magnets.

- Humid coastal areas may cause magnets to corrode faster.

- Electromagnetic fields nearby can interfere with the magnet's function.

What Happens with the Wrong Strength?

If the magnet is too weak:

- The door won't stay open, even with a light breeze.

- Holding power is inconsistent.

- The door might suddenly slam shut.

If the magnet is too strong:

- Closing the door becomes difficult.

- Hinges may experience unnecessary strain.

- The door or wall surfaces could get damaged.

Test It Before You Commit

Before mounting the magnet permanently, try this quick test [3]:

- Use strong adhesive tape to temporarily attach the components.

- Open the door fully and simulate breezes to see how it holds.

- Check how much effort it takes to close the door.

Once installed, keep the magnetic surfaces clean and inspect the hardware regularly [4] to ensure everything stays in top shape. Even with the right magnet strength, poor surface preparation can still lead to problems.

sbb-itb-7d66a95

5. Poor Surface Prep

Skipping surface preparation is a common DIY mistake that can ruin even the best magnet alignment. This crucial step plays a big role in whether your installation works as intended.

Key Steps for Proper Prep

- Use isopropyl alcohol to clean the surface and eliminate:

- Natural oils from your hands

- Dust, dirt, and debris

- Leftover cleaning product residue

To get the best results:

- Clean the area thoroughly with isopropyl alcohol.

- On painted surfaces, make sure the paint has fully cured (this usually takes 2-4 weeks).

- Allow the surface to dry completely after cleaning.

- Wear gloves while handling materials to avoid transferring oils.

Skipping these steps could make all your hard work with alignment and hardware selection pointless. And even perfect prep won’t help if your door stop is positioned incorrectly - more on that next.

6. Height Adjustment Errors

Improper height placement, much like vertical or horizontal alignment issues (see Section 1), can reduce magnetic efficiency. The ideal height - usually about ¾ of the door's height from the floor [5][2] - depends on several key factors.

Common Problems with Incorrect Height

- Weak magnetic hold due to misalignment

- Uneven pressure, leading to premature wear

- Tripping hazards caused by low placement

Key Considerations for Choosing the Right Height

When determining the installation height, pay attention to:

- Flooring type and transitions

- Presence of baseboards

Adjustments Based on Flooring

Different flooring types require tailored adjustments for accurate installation:

| Floor Type | Height Adjustment |

|---|---|

| Carpet | Include the carpet pile height in your measurements |

| Hardwood | Consider surface irregularities |

| Tile | Account for grout lines and uneven surfaces |

| Uneven Surfaces | Use leveling compounds before installation |

Tips for Accurate Installation

- Use a laser level to mark the correct placement

- Temporarily mount the hardware to test alignment

- Position the hardware to provide the best leverage [5]

Ensuring the correct height not only aligns the strike plate properly but also protects walls and prevents tripping hazards [1]. If the height is off, it can worsen issues like weak magnets (see Section 4) by reducing leverage.

Once the height is set, move on to final function testing (Section 7) to ensure everything works as it should.

7. Skipping Function Tests

Testing the functionality of a magnetic door stop is a step that many skip - but it’s absolutely necessary. Without proper testing, you risk issues like early failure or even safety concerns. This step ensures that everything - alignment, hardware choice, and placement - works as intended.

Key Function Tests to Perform

Here are the main checks you should focus on:

| Test | What to Do | What to Look For |

|---|---|---|

| Hold Strength | Apply gentle pressure | The door should stay put |

| Movement | Open and close 10 times | Smooth, consistent motion |

| Safety | Inspect visually | All parts securely in place |

Common Mistakes to Avoid

- Forgetting to account for how doors expand or shrink with the seasons

- Not testing how air currents might affect the door

- Skipping tests that apply force from different angles

How to Test Effectively

Follow this simple three-step approach:

- Initial Movement Check: Open and close the door repeatedly to confirm it moves smoothly.

- Magnet Strength Test: Apply light pressure to ensure the magnet holds the door securely.

- Environmental Testing: Check how the door performs with windows open and closed to simulate real-life conditions.

Simulating Real-World Scenarios

It’s important to test for things like:

- Changes in the door’s size due to weather

- How air currents impact the door’s stability

This is especially important for hidden designs like StealthStop, where the concealed mechanics demand precise testing to ensure proper function.

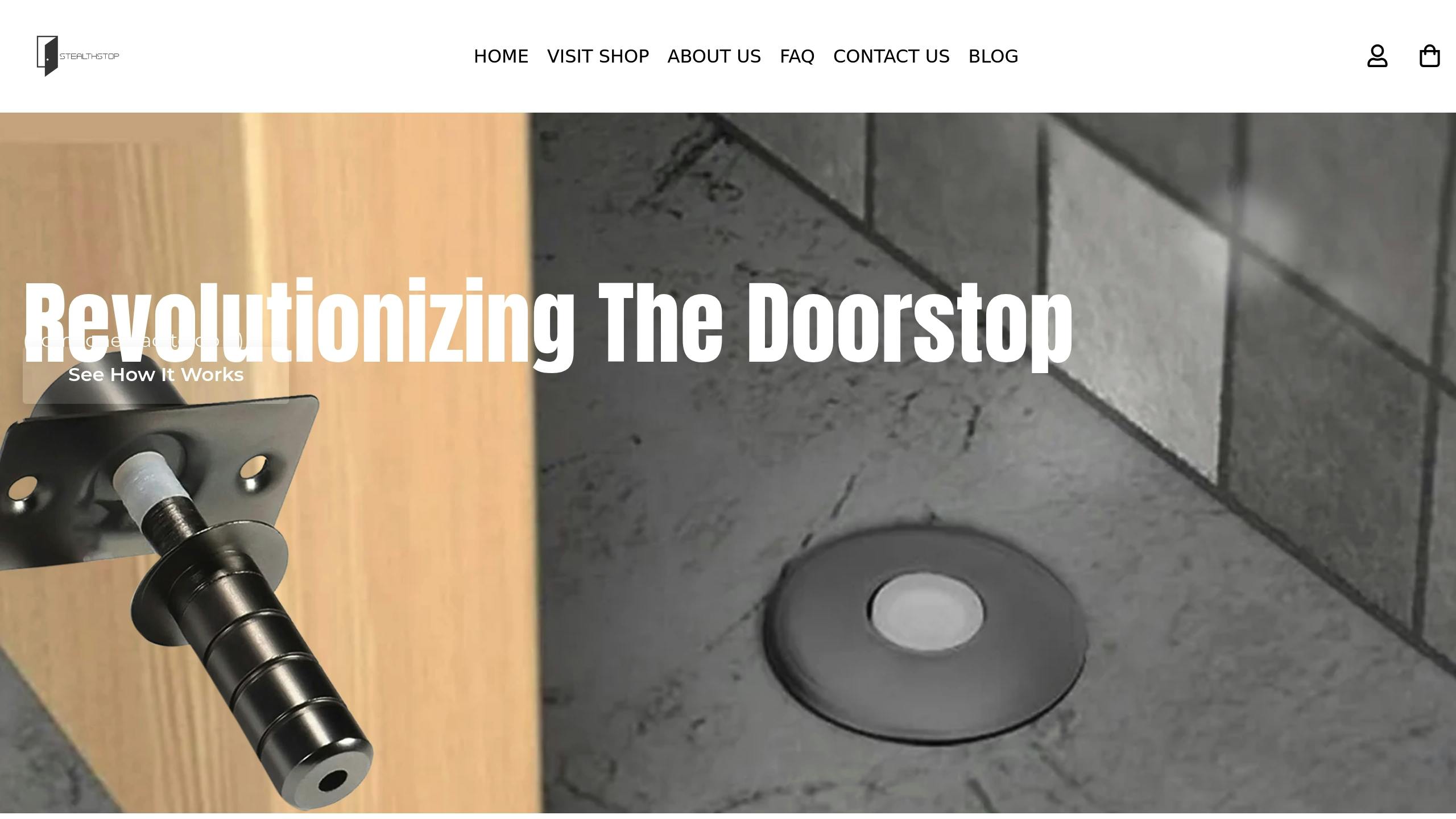

StealthStop Features and Benefits

StealthStop tackles common installation and performance challenges with carefully designed solutions that prioritize ease of use and reliability.

Smart Design Solutions

The product's low-profile design simplifies installation, reducing the likelihood of errors through precise engineering[5].

| Feature | Purpose |

|---|---|

| 25-lb neodymium magnet | Ensures proper holding strength |

| Mounting template | Simplifies alignment during setup |

| Stainless steel build | Resists wear and tear over time |

Installation Accuracy

The included mounting template and hardware take the guesswork out of installation, ensuring proper alignment and preventing common screw placement errors[5].

Performance Features

The 25-lb neodymium magnet offers dependable holding power across multiple door types:

- Works seamlessly with wood, metal, and glass doors without requiring additional plates[5].

- Its hidden mechanism prevents interference with door movement, addressing issues highlighted in Section 3[5].

This magnet also resolves strength miscalculations noted in Section 4, while the pre-drilled templates align perfectly with the functional testing requirements mentioned in Section 7[5].

Durability and Support

Built from stainless steel, StealthStop performs consistently, even in conditions where doors expand or contract with seasonal changes[5]. It installs in just three minutes and comes with a 30-day refund policy and a 1-year warranty, making it a reliable choice for homes, offices, and commercial spaces[5].

Conclusion

Avoiding these seven mistakes is key to ensuring your magnetic door stop works effectively while protecting your walls and doors. Proper installation not only prevents damage but also guarantees dependable performance. The focus should be on critical factors like alignment accuracy and choosing compatible materials.

Pay special attention to precise alignment, selecting the right hardware, and thorough testing - these are the pillars of a successful installation. Getting these right sets the stage for long-lasting reliability.

Products like StealthStop simplify the process by addressing common issues. Its integrated mounting template and 25-lb magnet system take the guesswork out of alignment and strength requirements. With stainless steel construction and pre-drilled templates, it also eliminates problems related to surface preparation and height placement. Following the provided instructions, you can achieve a secure installation in just three minutes.

FAQs

How high should door stops be?

The ideal height for a door stop is about three-quarters of the door's total height from the floor. For an 80-inch door, this would be 60 inches. This placement reduces stress on the hinges while providing a strong magnetic hold. It also helps prevent the door from flexing unnecessarily.

Here’s why this height works well:

- Reduces strain on hinges

- Prevents the door from bending

- Ensures a strong magnetic connection

The exact height can vary depending on the type of door:

| Door Type | Recommended Height |

|---|---|

| Tall Doors (84-96") | 63-72 inches |

| French Doors | Align with center rail |

| Glass Doors | Match the frame structure |

If you're installing it yourself, sticking to the three-quarters height rule ensures the door stop works effectively with the magnetic performance factors discussed earlier in Sections 4 and 6.