Magnetic door hardware is transforming how doors function, offering quieter, longer-lasting, and more efficient solutions compared to traditional mechanical systems. Here's a quick breakdown:

-

Key Benefits:

- Quiet operation with fewer moving parts.

- Low maintenance (no lubrication needed).

- Adjustable strength for various door weights.

- Sleek, modern designs.

-

Types of Magnetic Systems:

- Door Stops & Holders: Prevent door impact and keep them in place.

- Magnetic Latches: Use magnetic attraction for secure closures.

-

Permanent vs. Electromagnetic Systems:

- Permanent: No electricity required, works during power outages.

- Electromagnetic: Advanced control with high holding force but needs power.

-

Factors Affecting Performance:

- Air gaps, plate thickness, and magnet grade impact strength.

- Proper alignment and material quality are crucial for durability.

-

New Developments:

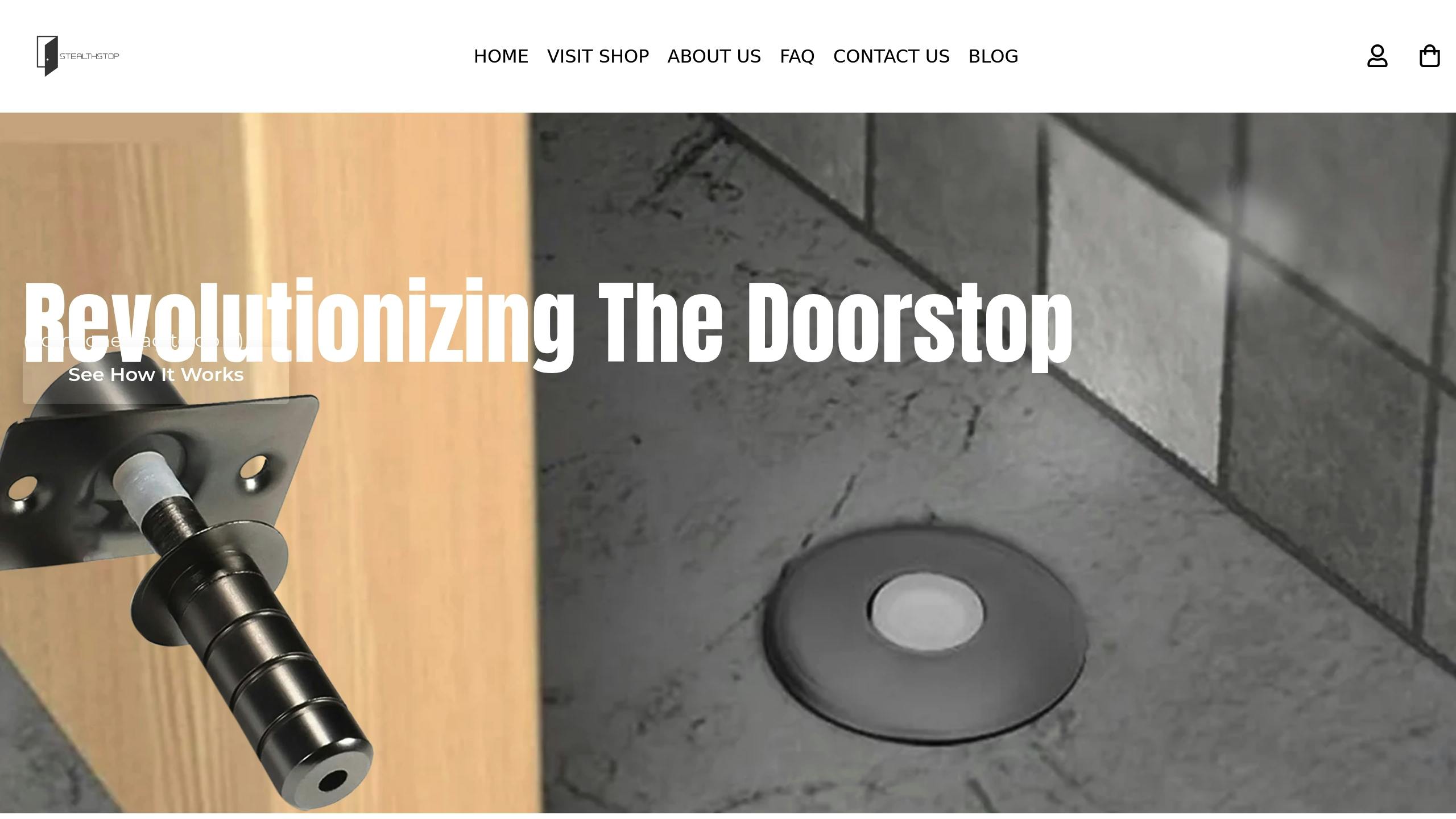

- Hidden magnetic stops like StealthStop improve aesthetics.

- Hybrid systems combine magnetic and mechanical features for efficiency.

Magnetic door systems are ideal for homes, commercial spaces, and industrial facilities, offering durability, energy savings, and modern design. Whether you're looking for quiet latches or high-security solutions, magnetic hardware is a reliable choice.

Magnetic Door Latch Technology Explained

How Magnets Work in Door Systems

Magnetic door systems rely on the basic principle of magnetic attraction between opposite poles. By using magnets and metal components, these systems achieve effective control without relying on complex mechanical parts. This approach ensures quieter operation and less frequent maintenance.

Basic Magnetic Principles in Doors

When a magnet interacts with a ferromagnetic plate - often made of high-quality steel - it creates a magnetic field that generates a holding force. This force is carefully adjusted to match specific door weights and operational needs.

| Magnetic Component | Function | Typical Application |

|---|---|---|

| Neodymium Magnet | Generates the holding force | Stop mechanisms/latch cores |

| Steel Armature Plate | Provides the contact surface | Frame mounting |

| Magnetic Core | Amplifies magnetic force | Electromagnetic systems |

These components form the basis of both permanent and electromagnetic systems, which differ mainly in their power requirements.

Permanent vs. Electromagnetic Systems

The choice between permanent and electromagnetic systems depends on the specific needs of the environment. Permanent magnetic systems are ideal for areas where power reliability is a concern, as they don't require electricity to function. They retain their strength over time and remain operational even during power outages.

Electromagnetic systems, on the other hand, require a constant power supply but offer more advanced control options. For example, they can provide holding forces exceeding 2000 lbs for high-security applications [1]. Additionally, they integrate easily with building management systems, enabling remote operation.

"In power outages, permanent magnets continue to function, while electromagnetic systems may release unless backed up by a battery."

Factors Influencing Magnetic Strength

The holding force of magnetic systems is measured in pounds-force (lbf), with standard door holders typically providing 25–40 lbs [5]. Several factors can influence the strength and performance of the magnet:

| Factor | Impact on Performance |

|---|---|

| Air Gap | Smaller gaps increase holding force |

| Plate Thickness | Thicker plates enhance attraction |

| Temperature | High temperatures can weaken force |

| Magnet Grade | Higher grades, like N52, offer stronger force |

Proper alignment between the magnet and the armature plate is essential for achieving maximum holding power. Ensuring smooth door operation also requires regular inspections of contact surfaces and maintaining the correct spacing between components [3]. These steps help keep the system working efficiently.

Magnetic Door Hardware Types

Magnetic principles are applied in door hardware through three main categories, each offering unique benefits and features.

Door Stops and Holders

Magnetic door stops prevent doors from hitting walls, keeping them in place without relying on traditional hardware. For example, StealthStop uses neodymium magnets embedded in stainless steel, providing a sleek, hidden solution [6].

| Feature | Traditional Stops | Magnetic Stops |

|---|---|---|

| Installation | Surface-mounted | Often concealed |

| Noise Level | May create impact sound | Silent operation |

| Aesthetics | Visible hardware | Can be invisible |

This design approach combines subtlety with functionality, paving the way for even more refined solutions like magnetic latches.

Magnetic Door Latches

Magnetic door latches ditch mechanical parts, relying on magnetic attraction instead. These systems typically involve a magnet in the door frame and a ferromagnetic strike plate on the door. Their holding strength varies based on application:

- Interior wood doors: 500-1,000 lbs holding force [4]

- Vault doors: 1,000-3,000 lbs holding force [4]

- Cabinets and furniture: Around 300 lbs holding force [4]

Hidden Magnetic Stop Comparison

| Feature | Hidden Magnetic Stops | Surface-Mounted Options |

|---|---|---|

| Visibility | Completely concealed | Partially visible |

| Installation Complexity | Requires precise fitting | Generally simpler |

| Holding Power | Strong (neodymium magnets) | Variable strength |

Modern systems now deliver holding forces exceeding 850 lbs in compact, efficient designs [1].

sbb-itb-7d66a95

Choosing the Right Magnetic Hardware

When selecting magnetic hardware, it's important to focus on three key factors: material quality, magnetic strength, and installation techniques. These elements ensure the hardware performs well and lasts over time.

Material Quality and Selection

The materials used in magnetic hardware play a big role in its durability and efficiency. High-quality materials not only improve magnetic transfer but also resist wear and tear in different environments. For example, stainless steel is ideal for areas with high humidity due to its corrosion resistance. On the other hand, neodymium magnets are known for their powerful hold in a compact size, though they are pricier than ceramic options.

| Material Type | Advantages | Best Applications |

|---|---|---|

| Stainless Steel | Resists corrosion, highly durable | Humid environments, exterior doors |

| Neodymium Magnets | Strong holding power, compact size | Heavy doors, security systems |

| Ceramic Magnets | Affordable, corrosion resistant | Light interior doors |

Magnetic Strength for Door Weight

To ensure proper functionality, the magnetic hardware must match the door's weight. A simple way to calculate this is by multiplying the door's weight by 1.5. The result gives you the minimum holding force needed for reliable performance.

Installation Best Practices

Good installation is just as important as choosing the right hardware. Follow these steps for the best results:

- Align carefully: Use templates provided by the manufacturer for precise placement.

- Clean surfaces: Ensure all mounting areas are free of dirt and debris.

-

Choose the right fasteners:

- For wood doors, use wood screws.

- For metal doors, opt for through-bolts.

- For glass doors, specialized mounting plates are required.

New Developments in Magnetic Doors

The magnetic door hardware industry is evolving, with new designs focusing on strength, efficiency, and smart technology. These advancements refine magnetic principles to meet modern design needs.

StealthStop Product Analysis

StealthStop takes hidden magnetic stops to the next level. Its neodymium magnetic mechanism ensures strong stopping power while keeping a sleek, discreet look.

Magnetic Systems for Frameless Doors

Frameless door designs have benefited from specialized magnetic systems that balance style and function. Rare earth magnets play a key role, offering:

| Feature | Benefit |

|---|---|

| Edge Integration | Concealed hardware for sleek aesthetics |

| Enhanced Field | Doubled strength for glass doors |

| Low-profile Mounting | Easy, minimalist installation |

Improvements in magnetic field shaping have boosted efficiency by up to 30% compared to older systems [8].

Combined Magnetic-Mechanical Systems

Hybrid magnetic-mechanical systems are now addressing complex door control needs with advanced features:

- Force-adaptive technology that adjusts hold strength across different temperatures, cutting energy use by up to 40% [9].

- Built-in usage tracking to streamline maintenance.

- A fail-safe mechanical backup for emergencies.

Conclusion: Magnetic Door Hardware Today

Magnetic door hardware has evolved to meet modern architectural needs, thanks to advancements in hybrid systems and concealed designs. Improved materials, like neodymium magnets, and precise engineering have made these systems a key part of contemporary design.

Today’s magnetic door systems provide:

- Energy efficiency: Up to 30% savings compared to traditional closers due to better door sealing [1].

- Durability: Reliable operation in extreme temperatures ranging from -60°F to 160°F [1].

Products like StealthStop's Invisible Magnetic Door Stopper show the market’s focus on blending subtle aesthetics with powerful magnetic functionality [10].

In healthcare, magnetic hardware has gained traction for its hygienic, easy-to-clean surfaces and potential for touchless operation [2]. These features align with the material benefits discussed earlier in Material Quality and Selection.

Looking ahead, magnetic-mechanical systems are expected to advance further with:

- The use of recyclable materials [1].

- Greater integration with smart home and building technologies.

- More eco-friendly manufacturing processes.

As architectural demands shift, magnetic door hardware continues to combine technical progress with design-focused solutions.

FAQs

How do magnetic door closers work?

Magnetic door closers rely on the pull between a magnet and a metal plate to close doors automatically. Here’s how the process works:

- When the door opens, the magnet and plate separate.

- The magnetic pull triggers the door to start closing.

- An adjustable mechanism regulates the closing speed.

- The door fully closes as the magnet holds it in place.

This system is quieter and causes less wear compared to traditional spring-loaded closers. It’s also built to last - tests show these closers can handle up to 1,000,000 cycles while maintaining consistent performance [3][7].

Are magnetic door latches good?

Magnetic door latches offer several advantages over mechanical ones:

| Feature | Advantage |

|---|---|

| Durability | Fewer moving parts mean less wear and tear [3] |

| Maintenance | Easy to clean, no lubrication required [2] |

| Operation | Quiet closing with one-handed use |

| Performance | Reliable holding force of 25-40 pounds [11] |

| Longevity | Lifespan ranges from 250,000 to 1,000,000 cycles [7] |

Neodymium-based latches are especially useful in places like healthcare facilities, where quiet and hygienic operation is a priority. These latches are perfect for high-traffic areas, offering long-lasting reliability and reduced upkeep. Their design and material quality make them a go-to choice for modern hardware needs.