Neodymium magnets are incredibly strong but highly vulnerable to humidity. Without proper protection, they corrode, weaken, and lose up to 50% of their magnetic strength in moist environments. Here's what you need to know:

- Why It Happens: Moisture seeps through coatings, causing oxidation and rust.

- Solutions: Protective coatings like nickel or epoxy, sealed housings, and proper storage (low humidity, silica gel).

- Alternatives: Samarium cobalt magnets resist corrosion better but are less powerful.

- Applications: From wind turbines to door stoppers, protective measures ensure performance in humid settings.

Quick Comparison

| Magnet Type | Humidity Resistance | Magnetic Strength | Common Applications |

|---|---|---|---|

| Neodymium | Low (needs coating) | Very High | Motors, wind turbines |

| Samarium Cobalt | High | High | Aerospace, marine equipment |

| Ferrite | Moderate to High | Moderate | Outdoor general-purpose use |

If you're using neodymium magnets in humid conditions, focus on coatings, storage, or consider alternatives like samarium cobalt for better durability.

Which coating is the best for your magnets?

Humidity Effects on Neodymium Magnets

Humidity can cause both chemical and physical damage to neodymium magnets, leading to permanent performance loss. Knowing how humidity affects these magnets is key to ensuring they function properly and last longer.

Corrosion Process

When moisture comes into contact with neodymium magnets, it can set off a damaging chain reaction. If water seeps through small flaws in the magnet's coating, oxidation begins, leading to rust and structural deterioration. This process happens faster in areas with high humidity, like tropical or coastal regions [1].

To combat this, manufacturers often use specialized coatings or sealed designs to shield magnets from moisture. These protective measures play a crucial role in extending the lifespan of neodymium magnets in damp conditions.

Magnetic Field Changes

Exposure to humidity doesn't just cause corrosion - it also weakens the magnet's magnetic field over time. This weakening can range from minor surface damage to severe corrosion that significantly reduces magnetic strength.

For precision-based uses, even small losses in magnetic power can be a big issue. For example, the StealthStop magnetic door stopper is designed to prevent these problems by using a protective system that shields its neodymium magnets from moisture, ensuring reliable performance even in humid settings.

In areas with above-average humidity, magnetic degradation happens much faster [1]. In such cases, materials like samarium-cobalt (SmCo) magnets are often preferred because they maintain their magnetic strength better in moist environments [2]. Choosing the right magnet material is essential when dealing with high humidity.

Magnet Types in Humid Settings

Permanent magnets react differently to humidity, so choosing the right material is crucial for specific uses.

Magnet Materials Comparison

Permanent magnets like neodymium, ferrite, and samarium cobalt each handle humid environments in unique ways.

| Magnet Type | Humidity Resistance | Magnetic Strength | Common Applications |

|---|---|---|---|

| Neodymium | Low (needs coating) | Very High | Wind turbines, motors (with protection) |

| Samarium Cobalt | High | High | Aerospace, marine equipment |

| Ferrite | Moderate to High | Moderate | General-purpose outdoor use |

Samarium cobalt magnets stand out for their excellent resistance to corrosion, making them the go-to choice for demanding fields like aerospace. Their reliability in humid conditions makes them a top pick for critical environments like marine and aerospace equipment [1].

Ferrite magnets, while not as strong as neodymium or samarium cobalt, naturally resist corrosion. This makes them an affordable option for outdoor applications where extreme strength isn’t needed [2].

Neodymium magnets, known for their unmatched magnetic strength, face challenges in humid settings. Without proper coatings or protection, they can lose up to 50% of their strength in such conditions [1]. Despite this drawback, their strength keeps them in demand, provided protective measures are in place.

Selecting the right magnet requires balancing strength and durability. For instance, aerospace sensors often rely on samarium cobalt magnets to meet environmental demands [1].

Now that we’ve compared materials, let’s look at practical ways to shield neodymium magnets from moisture.

sbb-itb-7d66a95

Protecting Neodymium Magnets

Neodymium magnets are sensitive to humidity, so taking steps to shield them from moisture is essential.

Surface Protection Methods

Protective coatings act as a barrier against moisture, helping to prevent corrosion. Nickel plating and triple-layer coatings (nickel-copper-nickel) are highly resistant to corrosion, making them suitable for industrial and marine uses. Epoxy coatings add another layer of defense, especially in challenging outdoor or extreme environments [1].

| Coating Type | Protection Level | Common Uses |

|---|---|---|

| Nickel/Ni-Cu-Ni | High to Very High | Industrial, marine |

| Epoxy | Very High | Outdoor environments |

| Zinc | Moderate | Indoor humid settings |

While coatings provide external defense, proper storage is just as important to minimize exposure to moisture.

Storage Guidelines

Store magnets in sealed containers with silica gel to absorb moisture. Keep storage conditions between 20-25°C with humidity levels below 50%. Always handle magnets with clean, dry gloves to avoid damaging their coatings. Regular inspections can catch early signs of corrosion before they become a problem [1][2].

Managing humidity in the storage environment is another key factor for maintaining magnet performance.

Humidity Control Methods

Industrial dehumidifiers are helpful for keeping storage areas at the right humidity levels. In marine applications, sealed magnetic units equipped with moisture-absorbing materials provide extra protection from the surrounding environment [1]. Without these precautions, magnets can corrode, weaken, and even fail in critical applications.

In manufacturing settings, proper ventilation and climate-controlled systems can prevent moisture buildup. Digital hygrometers allow for continuous monitoring to ensure conditions stay within safe ranges.

Applications and Solutions

High-Humidity Applications

Neodymium magnets are crucial in environments with high moisture levels, where specialized protective measures are needed to ensure they work reliably. In extreme conditions, like saltwater settings, Samarium Cobalt magnets are sometimes used instead because they resist corrosion better, even though they have less magnetic strength [1].

| Application | Protection Method | Key Consideration |

|---|---|---|

| Medical Equipment | Hermetic sealing | Resistance to sterilization |

| Food Processing | Food-grade coating | Resistance to chemicals |

| Industrial Sensors | Vapor barrier protection | Handling temperature changes |

These protective techniques are essential not just for industrial uses but also for everyday items designed to withstand humid conditions.

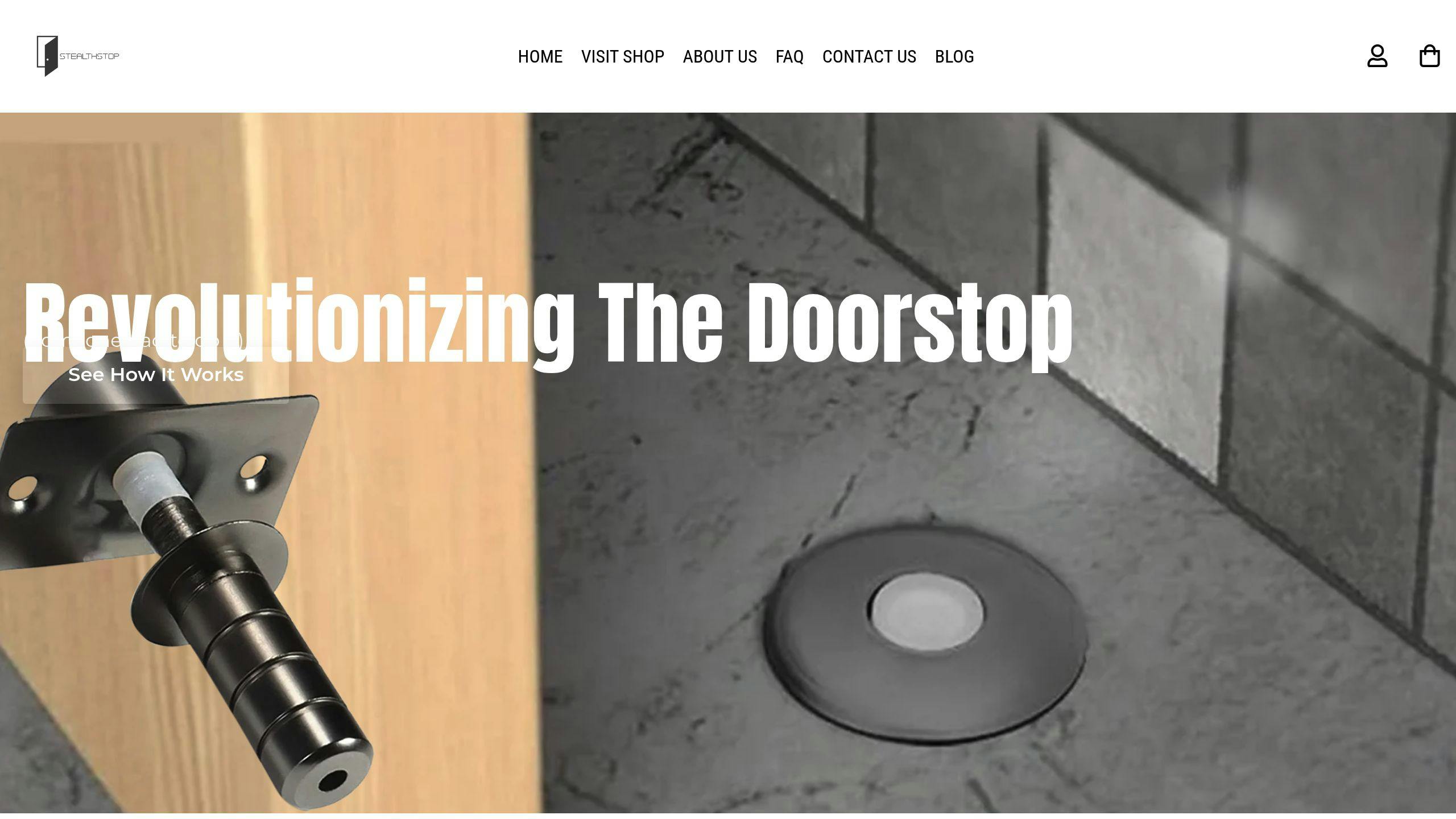

StealthStop Magnetic Door Stopper

The StealthStop Magnetic Door Stopper is a great example of how thoughtful design can address the challenges of using neodymium magnets in damp environments. Its waterproof construction and stainless steel casing make it suitable for both indoor and outdoor use in humid conditions.

This product showcases how a well-planned design can protect against humidity. The stainless steel casing prevents corrosion while keeping the magnet's strength intact in changing environments. Its sealed design ensures consistent performance on various door types, even in moisture-heavy areas. This demonstrates how selecting the right materials and protective features can extend the functionality of neodymium magnets in tough conditions [1].

This example highlights the effectiveness of the protective strategies discussed, proving that with the right design, neodymium magnets can thrive even in challenging, humid environments.

Conclusion

Main Points

To use neodymium magnets effectively, it's important to understand their sensitivity to humidity. Industries have developed various protective measures to tackle this issue.

| Protection Method | Common Use Case |

|---|---|

| Epoxy Coating | Everyday Applications |

| Nickel-Plating | Industrial Equipment |

| Stainless Steel Casing | Marine Environments |

Armed with these insights, let’s dive into practical tips for safeguarding neodymium magnets in damp conditions.

Usage Guidelines

When dealing with neodymium magnets in humid settings, proper care and protection are critical. Keep them in dry, controlled spaces and inspect frequently for signs of rust or damage [1][2].

For applications where humidity is unavoidable, focus on these essential steps:

- Assess the Environment: Determine the humidity levels in your specific use case.

- Pick the Right Protection: Select a coating or casing that matches the exposure level.

- Stick to Maintenance: Regularly monitor and control moisture to prevent long-term issues.

In situations requiring extreme moisture resistance, consider alternatives like Samarium Cobalt magnets. While they may sacrifice some magnetic strength, they excel in resisting corrosion, making them ideal for marine and similar high-moisture environments [1][2].