304 vs. 316 Stainless Steel: Best Choice for Magnetic Door Stoppers

by Shopify API on Feb 07, 2025

When choosing between 304 and 316 stainless steel for magnetic door stoppers, the decision mainly depends on where they’ll be used and the environmental conditions. 304 stainless steel is affordable and works well for indoor or standard environments. 316 stainless steel, with its added molybdenum, offers superior resistance to salt, humidity, and chemicals, making it ideal for coastal or harsh settings. While 316 costs 25-30% more, its durability can save on maintenance in tough environments.

Quick Comparison

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good for general use | Excellent in harsh conditions |

| Best Uses | Indoor, standard environments | Coastal, chemical, or marine |

| Cost | Lower | 25-30% higher |

| Durability | Good | Excellent |

For most indoor uses, 304 is sufficient. For coastal or chemically harsh areas, 316 is the better choice.

304 vs 316 Stainless Steel: Understanding Key Differences

Material Composition and Properties

The chemical makeup of 304 and 316 stainless steel plays a key role in their performance when used in magnetic door stoppers. Knowing these differences can help you choose the right material for specific installation needs.

Chemical Makeup Comparison

304 stainless steel contains 18% chromium and 8% nickel, which provides strong general corrosion resistance. On the other hand, 316 stainless steel includes 16% chromium, 10% nickel, and 2% molybdenum. This extra molybdenum boosts its ability to withstand chlorides and acids [1]. These variations are especially important for door hardware in demanding environments.

| Environment | 304 Performance | 316 Performance |

|---|---|---|

| Indoor Use | Excellent | Excellent |

| Coastal Areas | Fair | Excellent |

| Harsh Chemical Exposure | Poor | Excellent |

While corrosion resistance is a major factor, these compositions also affect other traits, like magnetic response.

Magnetic Response Differences

In their annealed state, both 304 and 316 stainless steel are non-magnetic. However, 316 has slightly lower magnetic permeability due to its higher nickel content [3]. That said, this difference doesn't matter for magnetic door stoppers like StealthStop, as the magnetic pull comes from neodymium magnets, not the steel.

Both grades are equally strong and durable, but 316 stands out for its resistance to pitting and crevice corrosion, particularly in chloride-heavy conditions [1][4]. For magnetic door stoppers, these material properties affect not just durability but also how well they hold up over time in tough environments.

Understanding these factors is key when evaluating how each grade performs in areas prone to rust and corrosion.

Rust and Corrosion Protection

Moisture and Salt Air Performance

For magnetic door stoppers in damp or coastal areas, corrosion resistance is a key factor. Thanks to the molybdenum in 316 stainless steel, it performs exceptionally well in salt air environments. This is particularly important in coastal regions, where salt spray speeds up the corrosion process.

While 304 stainless steel can start to corrode in just a few months under these conditions, 316 stainless steel holds up even in harsh environments. This makes 316 the better choice for coastal homes, offices, or commercial spaces that need durable door hardware.

| Environment | 304 SS Durability | 316 SS Durability | Recommended Grade |

|---|---|---|---|

| Indoor Dry | Excellent (15+ years) | Excellent (15+ years) | Either Grade |

| High Humidity | Good (5-10 years) | Excellent (15+ years) | 316 |

| Coastal/Marine | Poor (2-5 years) | Excellent (10-15 years) | 316 Only |

In addition to environmental conditions, the type of cleaning products used can also affect the lifespan of stainless steel door hardware.

Chemical Cleaning Effects

Cleaning agents can have a major impact on the durability of door hardware. Frequent use of harsh cleaners can cause 304 stainless steel to discolor or develop pits. In contrast, 316 stainless steel resists chemical damage, keeping its appearance and structural integrity intact. This makes it a smart option for locations like healthcare facilities or commercial spaces that require frequent sanitization.

"316's superior corrosion resistance extends hardware lifespan in harsh environments, offering long-term savings despite higher upfront costs" [1][3].

sbb-itb-7d66a95

Strength, Lifespan, and Price

Physical Strength Comparison

The physical properties of 304 and 316 stainless steel play a key role in the performance of magnetic door stoppers. Thanks to its molybdenum content, 316 stainless steel offers better durability, making it a solid choice for areas with heavy use. When incorporated into magnetic door stoppers, 316 ensures reliable function even under constant stress.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Tensile Strength | 380-600 MPa | 400-620 MPa |

| Durability | Good | Excellent |

| Resistance to Temperature Fluctuations | Standard | Enhanced |

Price and Market Supply

For those looking for a more economical option, 304 stainless steel is widely used in door hardware manufacturing. On the other hand, the added molybdenum in 316 stainless steel increases its production cost, making it about 25-30% more expensive than 304. However, in challenging environments, 316's durability can help reduce long-term maintenance expenses.

Market availability also plays a role in material selection. 304 stainless steel is easier to source and works well for most standard applications. While 316 comes with a higher price tag, its superior performance has made it a go-to choice for commercial settings and areas with heavy foot traffic.

Choosing between these two grades depends on how you prioritize strength, durability, and cost for your specific application.

Steel Grade Selection Guide

Selection Criteria

| Environment Type | Recommended Grade | Key Advantages |

|---|---|---|

| Indoor Residential | 304 | Affordable option with standard corrosion resistance |

| Coastal Properties | 316 | Excellent resistance to salt and chlorides |

| Commercial Kitchens | 316 | Withstands frequent exposure to chemical cleaners |

| Standard Office | 304 | Durable and budget-conscious |

| Chemical Facilities | 316 | Handles exposure to acids effectively |

When deciding on the right steel grade, keep these factors in mind:

- Location Exposure: Consider if the area is near saltwater, uses chemical cleaners, or has high humidity.

- Budget: Keep in mind that 316 stainless steel typically costs 25-30% more than 304.

- Maintenance: Think about the cleaning and upkeep required over time.

Now, let’s see how StealthStop’s design utilizes these materials to ensure top-tier performance.

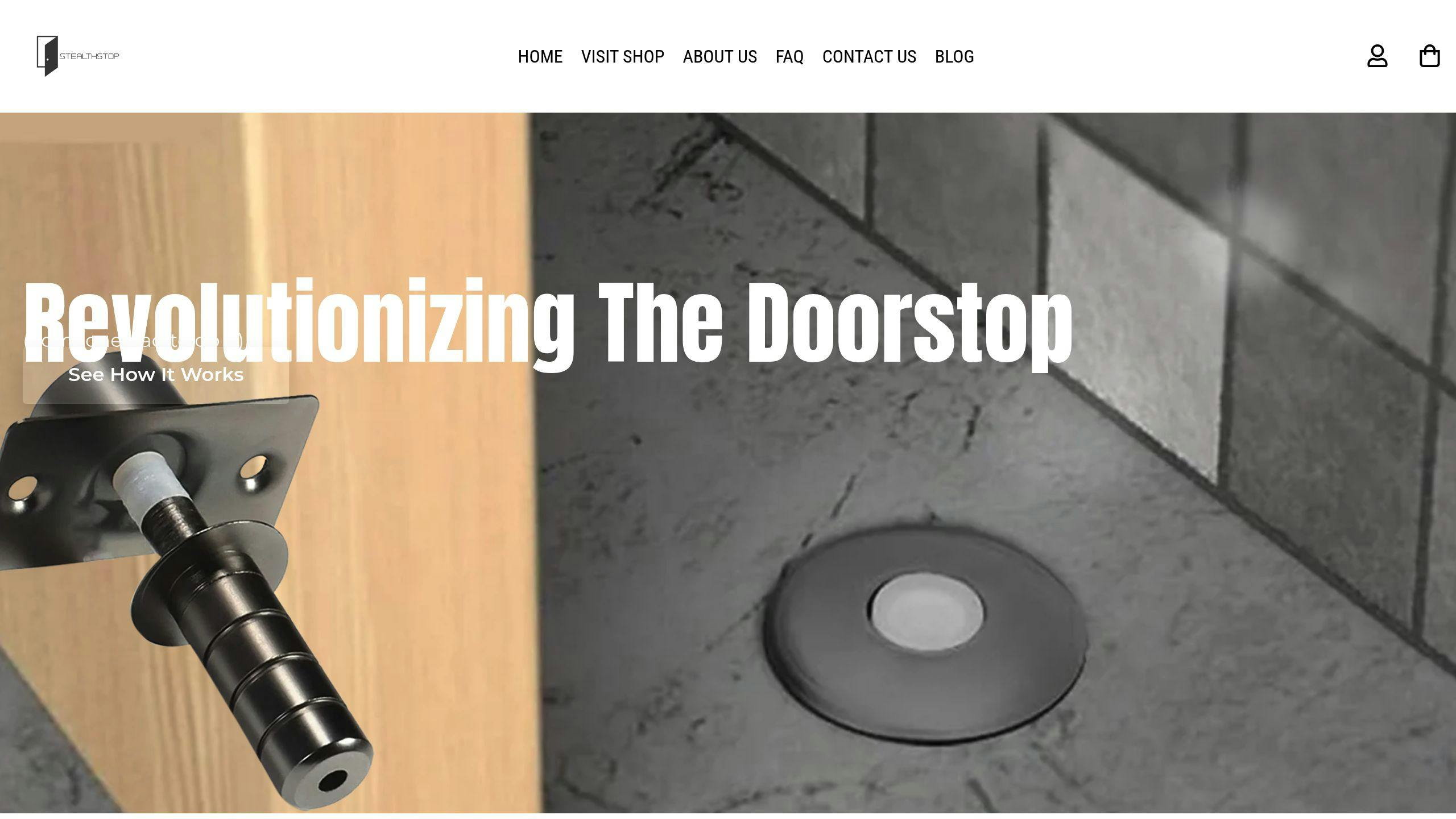

StealthStop Product Features

StealthStop’s Invisible Magnetic Door Stopper showcases smart use of stainless steel in hardware design. Built with high-quality materials, it balances durability and style. The neodymium magnetic system guarantees reliable performance regardless of the steel grade, making it suitable for a variety of settings.

Highlighted features include:

| Feature | Advantage |

|---|---|

| Neodymium Magnetic System | Reliable and consistent across environments |

| Flexible Installation | Works well in diverse conditions |

| Sturdy Construction | Ensures long-lasting performance |

For most indoor uses, 304 stainless steel offers great value. However, for harsher conditions - like coastal areas or spaces requiring frequent cleaning - 316 stainless steel is the better choice for its enhanced resistance and durability.

Summary and Recommendations

Main Differences Summary

Choosing between 304 and 316 stainless steel for magnetic door stoppers comes down to the environment they're used in and your budget. Here's a quick comparison:

| Characteristic | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Composition | 18% chromium, 8% nickel | 16% chromium, 10% nickel, 2% molybdenum |

| Best Uses | Indoor residential, standard office environments | Coastal properties, chemical facilities, marine settings |

| Corrosion Resistance | Suitable for general use | Higher resistance to chlorides and acids |

| Cost Factor | Standard pricing | 25-30% higher cost |

By using stainless steel, StealthStop ensures their magnetic door stoppers are built for durability and reliable performance.

StealthStop Quality Overview

StealthStop's Invisible Magnetic Door Stopper is designed with high-quality materials to meet industry standards. The use of premium stainless steel ensures the product performs well in both residential and commercial spaces, even in tough environments like coastal areas.

Key features of the product include:

| Feature | Benefit |

|---|---|

| High-Grade Stainless Steel Construction | Increased durability and resistance to corrosion |

| Neodymium Magnetic System | Reliable performance in various conditions |

| Waterproof Design | Ideal for humid or wet environments |

| Universal Compatibility | Works with a variety of door types and settings |

To ensure long-lasting performance, the American Society for Testing and Materials (ASTM) advises factoring in both the installation environment and maintenance needs when selecting door hardware materials [1][2]. While 316 stainless steel may cost more upfront, its excellent corrosion resistance can reduce maintenance expenses and extend the product's lifespan in harsher conditions.

FAQs

What is the best door hardware for coastal areas?

For coastal areas, 316 stainless steel stands out as the top choice. It’s highly resistant to chlorides and salt air, thanks to its 2% molybdenum content, which provides extra protection against corrosion. This makes it perfect for harsh coastal conditions where durability is key [1].

If you’re considering alternatives, you might wonder whether 304 stainless steel could work in such environments.

Is 304 stainless steel ok for marine use?

While 304 stainless steel works well in protected indoor marine settings, it’s not the best option for direct exposure to seawater or areas with high salt levels [1][3]. It offers decent corrosion resistance but falls short compared to 316 stainless steel in tougher marine conditions.

| Environment Type | 304 Suitability | Recommended Grade | Maintenance Tips |

|---|---|---|---|

| Protected Indoor Marine Areas | Good | Either Grade | Regular cleaning advised |

| Coastal Indoor Spaces | Moderate | 316 | Use additional protection |

| Direct Salt Exposure | Limited | 316 Only | Frequent inspections needed |

| High Humidity Areas | Fair | 316 | Apply protective coatings |

For long-term durability in marine environments, limit the use of 304 stainless steel to areas with minimal exposure to corrosive elements [1][2]. Opt for 316 stainless steel for more demanding applications.